The content of this page is exported from a Jupyter notebook.

The calibration or the EuroPi analog input and analog outputs is quite simple.

To calibrate the input, we apply a reference voltage to the analog input and measure the ADC (Analog to Digial Converter) output. We repeat this process several times with different reference voltages spanning the whole analog input range. To get the ADC reading corresponding to other voltages, we simply interpolate the value with a linear approximation.

Calibrating the CV outputs requires a bit more work as the Raspberry Pi Pico does not have a DAC (Digital to Analog Converter). The outputs are PWM (Pulse-Width Modulation) oscillators. A low-pass filter is used to smooth out the rapid switching of the PWM to create a stable voltage. To generate a specific voltage, we vary the duty-cycle of the PWM oscillator.

To calibrate the analog output, we select a reference voltage and adjust the duty-cycle until the reference voltage is measured at the output using a precise voltmeter. We repeat this process with different reference voltages spanning the entire analog output range and, like for the analog input, we use linear interpolation to determine the duty-cycle for other voltages.

import matplotlib.pyplot as plt

import numpy as np

MAX_UINT16 = 65535

MIN_INPUT_VOLTAGE = 0

MAX_INPUT_VOLTAGE = 12

MIN_OUTPUT_VOLTAGE = 0

MAX_OUTPUT_VOLTAGE = 10

def clamp(value, low, high):

return max(min(value, high), low)

# just an utility function

def create_plot(x_min=0, x_max=10, ticks=1):

fig = plt.figure()

ax = fig.add_subplot(1, 1, 1)

major_ticks = np.arange(x_min, x_max+1, ticks)

ax.set_xticks(major_ticks)

ax.grid(which='both')

ax.set_axisbelow(True)

return ax

Analog Input (ain) calibration procedure

The reference voltages used for the calibration are :

# reference voltages :

INPUT_CALIBRATION_POINTS = [0, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10]

To read the ADC output we use the function :

ADC_reading = ain.read_u16()

For a single reading, we call read_u16() several time and use the average value as the reading value. This allow to smooth-out the inherent ADC noise.

def sample():

readings = []

for reading in range(256):

readings.append(ain.read_u16())

return round(sum(readings) / 256)

Once we have measured the different reference voltages defined above, we get a serie of corresponding ADC readings :

# ADC readings :

INPUT_CALIBRATION_VALUES = [523, 3950, 7396, 11242, 15464, 19698, 24520, 29801, 34257, 38762, 44268]

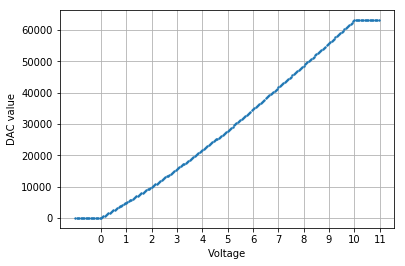

We can represent these calibration points on a graph :

ax = create_plot()

p = ax.scatter(INPUT_CALIBRATION_POINTS, INPUT_CALIBRATION_VALUES, s=80)

p.set_label('ADC readings')

ax.legend()

plt.xlabel('Ref voltage') # reference voltages as X

plt.ylabel('ADC output') # ADC readings as Y

plt.show()

Saving of the calibration results :

Once all the references voltage have been applied and the ADC readings done, these values are saved in the calibration.py file. This file will be loaded by the firmware and the values used to correct the ADC readings when calling europi.voltage() for example.

Usage of the calibration values in the firmware :

Each pair or calibration point is connected with a linear segment of the form :

y = m*x + b

mis the gradient (or slope)bis theyoffset at the origin of the segment.

The gradient is calculated with gradient = (y1-y0) / (x1-x0)

In our case the y values are the ADC readings, and the x values are the reference voltages used for the calibration.

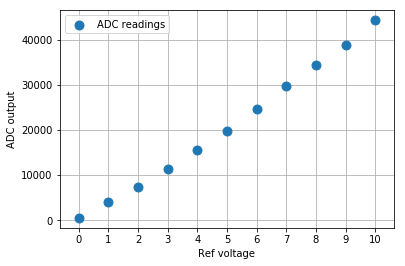

We can represent these segments in a graph :

Please note that the axis have been swapped, X is now the ADC readings.

ax = create_plot(0, 65535, 10000)

p1, = ax.plot(INPUT_CALIBRATION_VALUES, INPUT_CALIBRATION_POINTS, '#555555')

p2 = ax.scatter(INPUT_CALIBRATION_VALUES, INPUT_CALIBRATION_POINTS, s=80)

p2.set_label('calibration points')

ax.legend()

plt.xlabel('ADC value')

plt.ylabel('Voltage')

plt.show()

Gradients precomputation :

We can precompute these segments' gradients in advance. This will allow for a slightly faster correction computation when we read a voltage :

gradients = []

for index, value in enumerate(INPUT_CALIBRATION_VALUES[:-1]):

gradients.append(

(INPUT_CALIBRATION_POINTS[index + 1] - INPUT_CALIBRATION_POINTS[index]) /

(INPUT_CALIBRATION_VALUES[index + 1] - value))

We re-use the last gradient for the ADC values that exceed the last calibration point :

gradients.append(gradients[-1])

result :

gradients : 0.000292, 0.000290, 0.000260, 0.000237, 0.000236, 0.000207, 0.000189, 0.000224, 0.000222, 0.000182, 0.000182

How is the calibration applied :

We want to know the voltage that correspond to the following ADC reading :

reading = 25000

Begin by finding the first segment that includes our reading :

index = next(index for index, r in enumerate(INPUT_CALIBRATION_VALUES) if r >= reading) - 1

result :

index = 6 (segment 24520..29801)

Then, calculate the corresponding value (voltage) with the linear equation formula :

y = offset + (slope * x)

In the above formula, offset is the y value at x=0 (origin).

In our case, the origin point is (INPUT_CALIBRATION_POINTS[index], INPUT_CALIBRATION_VALUES[index])

We already have the slope value, this is the segment's gradient we precomputed before.

We have a special case if the reading is lower then the lowest calibration reading, in this case index=-1 and we simply say that the voltage is 0 (since we do not go into negative voltage).

Example :

if index < 0:

cv = 0

else:

cv = INPUT_CALIBRATION_POINTS[index] + gradients[index] * (reading - INPUT_CALIBRATION_VALUES[index])

result :

cv = 6 + 0.000189 * (25000-24520) = 6.09 V for ADC reading = 25000

Outputs calibration :

We use the analog input (ain) to calibrate the analog outputs. We use ain to measure the output voltage. It is therefore important that the analog input has been calibrated beforehand.

For this, we need to know what is the ADC value that coresponds to a given voltage.

How to calculate the analog input ADC value for a specific voltage :

This is very similar to the previous computations used to get the real voltage from an ADC reading. We use the same precomputed gradients as before but, instead of finding the voltage from and ADC value, we want to get the ADC value for a given voltage.

Let's say we want to calibrate our output to generate 5.00 V :

cv = 5.00

Since we use ain to measure the output, we must therefore determine what is the ADC value which corresponds to a value of 5V at ain.

Find the first segment that includes the given voltage :

index = next(index for index, v in enumerate(INPUT_CALIBRATION_POINTS) if v >= cv) - 1

result :

index = 4 (segment 4..5)

Calculate the corresponding value (ADC reading) with the linear equation formula :

if index < 0:

expected_reading = INPUT_CALIBRATION_VALUES[0]

else:

expected_reading = int(INPUT_CALIBRATION_VALUES[index] + (cv - INPUT_CALIBRATION_POINTS[index]) / gradients[index])

result :

ADC value must be 19698 for ain = 5.0 V

Calibration of the output :

To output a voltage we use the following function :

pin.duty_u16(N)

N is a 16 bits number (0..65535).

The calibration process is simple :

We set the output duty_cycle to generate a voltage, measure it with ain and compare against a reference ain reading. We adjust the output voltage until the ain reading matches the reference value.

- generate a voltage with a duty_cycle N

- measure this voltage with ain ADC

- correct the output voltage duty_cycle (N) and try again until the ain reading matches the reference value

We do this for every 1V from 0 to 10V.

Implementation note: since we calibrate for 1, 2, 3 ... 10V, we can directly use the reference output voltage as the index of the output calibration list.

output_duties = [] # this list will hold the output calibration values

for cv in range(1, 11):

try:

index = next(index for index, v in enumerate(INPUT_CALIBRATION_POINTS) if v >= cv)

except StopIteration:

# end of list reached

index = 10

expected_reading = int(INPUT_CALIBRATION_VALUES[index] + (cv - INPUT_CALIBRATION_POINTS[index]) / gradients[index])

duty = 0

reading = 0

while abs(reading - expected_reading) > 0.002 and reading < expected_reading:

cv1.duty_u16(duty) # output a voltage

sleep(0.1) # wait for the voltage to stabilize (only necessary for the calibration)

duty += 10

reading = sample() # read the ADC

output_duties.append(duty)

The results above, saved in output_duties are the reference values for the output calibration.

We write these values as OUTPUT_CALIBRATION_VALUES :

OUTPUT_CALIBRATION_VALUES=[0, 4870, 9820, 15530, 21630, 27810, 34640, 41640, 48630, 55770, 63090]

Since we used a range(0, 11) for the calibration points, we have :

OUTPUT_CALIBRATION_POINTS=[0, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10]

Use the output calibration data to generate a precise voltage :

Optimisation note : with the above definition we always have OUTPUT_CALIBRATION_POINTS[index] == index

when we enumerate(OUTPUT_CALIBRATION_POINTS). We can therefore replace OUTPUT_CALIBRATION_POINTS[index] with index and OUTPUT_CALIBRATION_POINTS[index+1] with index+1.

Again, the usage is very similar to the one applied to the input calibration data. We connect the output calibration values with linear segments and use the simple linear equation to interpolate the values.

Output gradients precomputation :

out_gradients = []

for index, value in enumerate(OUTPUT_CALIBRATION_VALUES[:-1]):

out_gradients.append(

(index + 1 - index) /

(OUTPUT_CALIBRATION_VALUES[index + 1] - value))

out_gradients.append(out_gradients[-1])

result :

out_gradients : 0.000205, 0.000202, 0.000175, 0.000164, 0.000162, 0.000146, 0.000143, 0.000143, 0.000140, 0.000137, 0.000137

Usage of the calibration to get the output PWN duty cycle value :

voltage = 2.50

index, decimal = (int(voltage // 1), voltage % 1)

dac = int(OUTPUT_CALIBRATION_VALUES[index] + (decimal / out_gradients[index]))

result :

index = 2

duty_cycle = int(9820 + (0.5 / 0.000175)) = 12675

Optimisations :

We can simplify the out_gradients precomputation with

(index + 1 - index) == 1

and, if we don't do the 1 / (...) division :

out_gradients = []

for index, value in enumerate(OUTPUT_CALIBRATION_VALUES[:-1]):

out_gradients.append(OUTPUT_CALIBRATION_VALUES[index + 1] - value)

out_gradients.append(out_gradients[-1])

the output duty cycle computation becomes :

duty_cycle = int(OUTPUT_CALIBRATION_VALUES[index] + (decimal * out_gradients[index]))

Tests

Some quick tests to verify the above process do not generate invalid values.

Input

def read_voltage(reading):

try:

index = next(index for index, v in enumerate(INPUT_CALIBRATION_VALUES) if v >= reading) - 1

except StopIteration:

index = len(INPUT_CALIBRATION_VALUES) - 1

if index < 0:

cv = 0

else:

cv = INPUT_CALIBRATION_POINTS[index] + gradients[index] * (reading - INPUT_CALIBRATION_VALUES[index])

return clamp(cv, MIN_INPUT_VOLTAGE, MAX_INPUT_VOLTAGE)

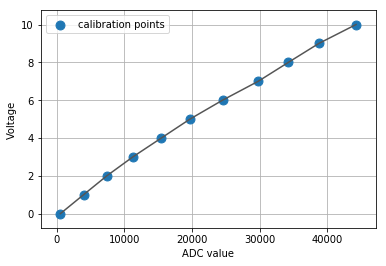

x = range(-11000, 65536, 5)

y = list(read_voltage(r) for r in x)

ax = create_plot(-10000, 65535, 10000)

ax.scatter(x, y, s=2)

plt.xlabel('ADC value')

plt.ylabel('Voltage')

plt.show()

Note: negative ADC value have no meaning; it's just for testing that the formula can accept any value.

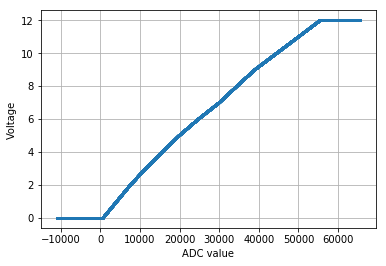

Output

OUTPUT_CALIBRATION_VALUES=[0, 4870, 9820, 15530, 21630, 27810, 34640, 41640, 48630, 55770, 63090]

def dac(voltage):

voltage = clamp(voltage, MIN_OUTPUT_VOLTAGE, MAX_OUTPUT_VOLTAGE)

index, decimal = (int(voltage // 1), voltage % 1)

return clamp(int(OUTPUT_CALIBRATION_VALUES[index] + (decimal * out_gradients[index])), 0, MAX_UINT16)

## If we want to accept any positive voltage :

# def dac(voltage):

# index, decimal = (int(voltage // 1), voltage % 1)

# if index >= len(OUTPUT_CALIBRATION_VALUES):

# offset = OUTPUT_CALIBRATION_VALUES[-1]

# gradient = out_gradients[-1]

# decimal = decimal + (index - len(OUTPUT_CALIBRATION_VALUES) + 1)

# else:

# offset = OUTPUT_CALIBRATION_VALUES[index]

# gradient = out_gradients[index]

# return clamp(int(offset + (decimal / gradient)), 0, MAX_UINT16)

x = np.arange(-1, 11, 0.05)

y = list(dac(v) for v in x)

ax = create_plot(x_max=12)

ax.scatter(x, y, s=2)

plt.xlabel('Voltage')

plt.ylabel('Duty cycle value')

plt.show()